Delta’s Blown Film Extruder Solution integrates all the stations along the production line by establishing an open communication architecture, and saves the labor cost needed in onsite parameter adjustment.

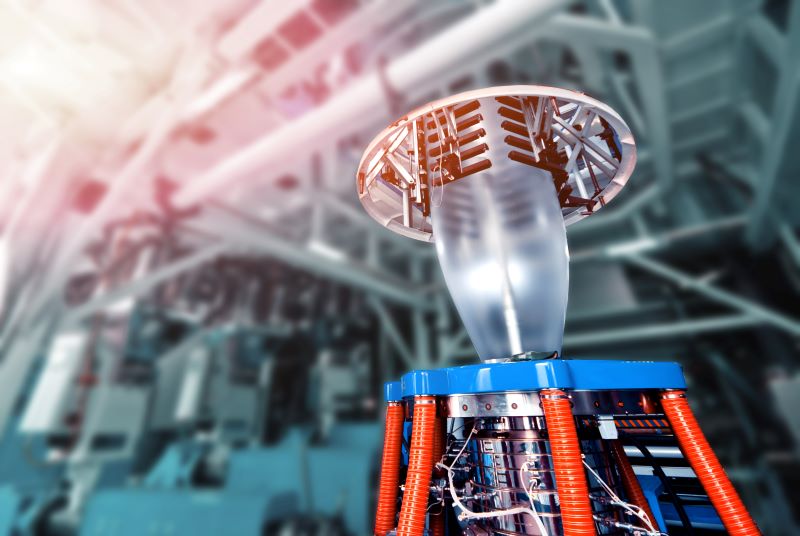

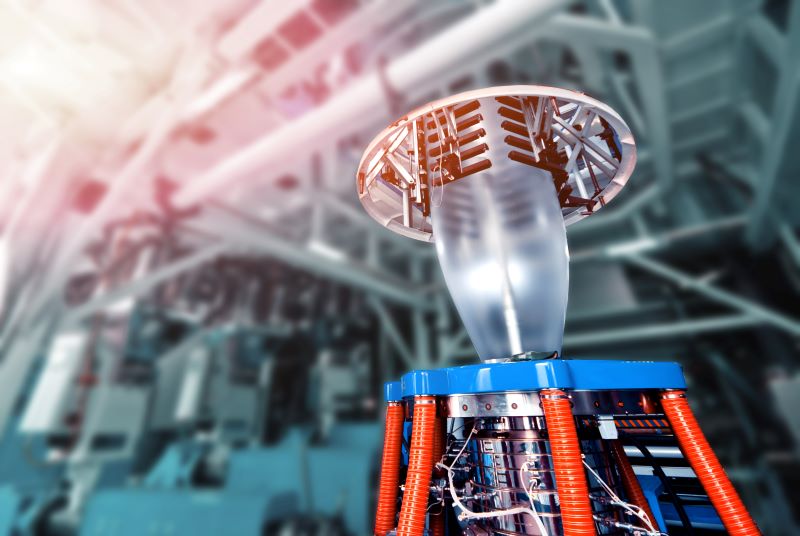

To precisely control the temperature of the rotary die head, Temperature Controller DT Series are installed on the rotary die head and transmit the collected data to the HMI via wireless network by IEEE 802.11 WLANs DVW series, solving the difficulties of temperature data collection and wiring on the rotary die head.

Delta’s Multi-Channel Modular Temperature Controller DTM Series control up to 64 temperature points, effectively saving wiring costs. The Human Machine Interface DOP-100 Series connects all the station data and achieves one-stop parameter adjustment based on processing needs.