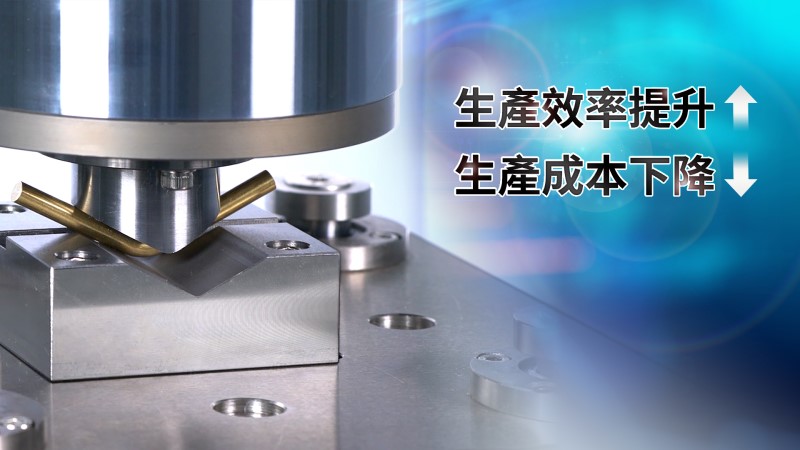

Delta Electric Servo Press features intelligent and friendly user interfaces suitable for pressing applications for gearing components, motor-driven machines, metal parts, and electrical parts.

The Servo Press can monitor, control, and update the data during the whole process. It keeps consistent standards throughout settings to avoid technical gaps and stabilize product quality.

Delta Electric Servo Press integrates IT and OT technologies. It collects data via peripheral devices and uploads it to the back-end system and records, stores, tracks, auto-generates various reports, and connects to the MES through PC software to achieve the smart manufacturing vision.

Delta’s Electric Servo Press features comprehensive production tracking solutions and quantitative data to assist admins in scheduling maintenance according to operating conditions, which helps enhance productivity and decrease defect rates.

Delta’s Electric Servo Press features high precision, smart functions, and friendly interface for a significant increase in productivity. The highly compatible design offers flexibility for adopting companies and satisfies their optimizing and vision requirements for resource arrangements and a solid foundation for smart transformation.